Logiball Inc. FR News

Understanding the Chemical Grouting Process

The Chemical Grouting process has proven to be very effective and long lasting.

Chemical grouting is one of the oldest techniques used to stop ground water infiltration into sewer collection systems. Unfortunately, it is also one of the most misunderstood. In order to gain a better understanding of grouting it helps to have a clear picture of the sewer construction methods that were used over the past 100 years. This knowledge will help you appreciate why this simple and versatile maintenance process is so effective at reducing infiltration.

THEN AND NOW

If you were a “sewer archeologist” and peeled away layer upon layer of the earth and pavement you would soon come across this network of buried gas, water, sewer and storm drainage pipes. Until recently all piping systems were directly buried. Soil was removed from the top down, pipe was laid in the trench and then back-filled. The result is a network of intersecting back-filled earth trenches, starting with building and home foundations, and leading to the main sewer trench. The sewer pipes tend to be the deepest as they slope gently downward from under building foundations. They are bedded in earth and gravel during construction to facilitate uniform sloping and joint alignment. The sewer joints were at first not sealed. But eventually tar, oakum, cement and even rubber gaskets were employed. Much of this work took place 60 years ago or more as the cities and suburbs grew following WWII. Over time, many of these joints have decayed and failed to varying degrees.

Today these interconnected utility sewer trench systems have evolved into massive ground dewatering systems. The crisscrossing and interconnection of all these utility trenches collects and channels surface and ground water into our sewer collection system trenches. This water percolates down into the pipe bedding around the sewer pipe and flows downward under the force of gravity like a “French Drain”, thus dewatering a broad area by moving ground water thru the sewer pipe bedding gravel.

Unfortunately, due to decaying joint materials, this ground water inevitably “infiltrates” into the collection system through open failed joints. This infiltration is obviously a bad thing, but few people outside the sewer collection and treatment profession really understand how it comes into being.

CHEMICAL GROUTING BASICS

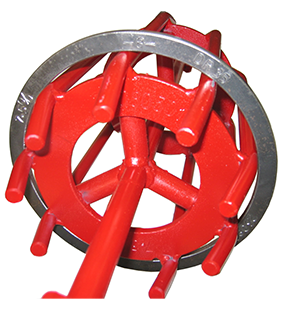

Chemical grouting is a soil sealing and stabilization process that works outside the sewer pipes in the backfilled sewer trench. It is a tool to control ground water infiltration into sewer system piping, which came into existence about 50 years ago. At that time Dr.Reuben H. Karol, working for American Cyanamid Company and Rutgers University, wrote a book titled Chemical Grouting and Soil Stabilization. That book and the process it described laid out the basic concept used to develop the sewer chemical grouting process.

SEALING WITH GROUT

Crews inject solution chemical grouts through the sewer faults pipe joints that are the infiltration channels for ground water entering the collection system. These grouts retain the consistency of water, and as they are injected into the adjacent bedding soil, they displace the air and water between soil particles and rapidly gel in these void spaces. Once gelled, the grout binds the soil into a cohesive mass covering, blocking the point of ground water leakage into the sewer pipe. This “seals the soil”, stopping ground water peculation thru the soil and into the sewer pipe. With up to 50% void areas in back-fill soils, this process has proven to be very effective and long lasting.

Grouting is also used extensively for sealing lateral connections because it does not depend on an internal surface chemical bond to the existing lateral or mainline pipe. Lateral connections have the least consistency as to method and quality because they were typically an “after the fact hook up” often done with minimal or no inspection. Laterals also have non-uniform connection geometry, numerous adjacent pipe joints and bends of varying degrees. Recently, grouting has been used extensively for lateral service tap cut outs in lined sewer pipes to seal the annulus formed by the old pipe inner wall and new liner exterior wall.

Many times we are taught a process without a clear understanding of the purpose and end result. Hopefully this information will allow you to be more effective in your work. Rehabilitating and maintaining the performance, efficiency and integrity of piping systems is a proud part of our profession.

For more information call 1-800-246-5988 or email info@logiball.com

Download PDF

Suivez-nous sur LinkedIn

Suivez-nous sur LinkedIn Suivez-nous sur YouTube

Suivez-nous sur YouTube