Logiball Inc. News

Grout Sealing Lateral Connections To Reduce Infiltration

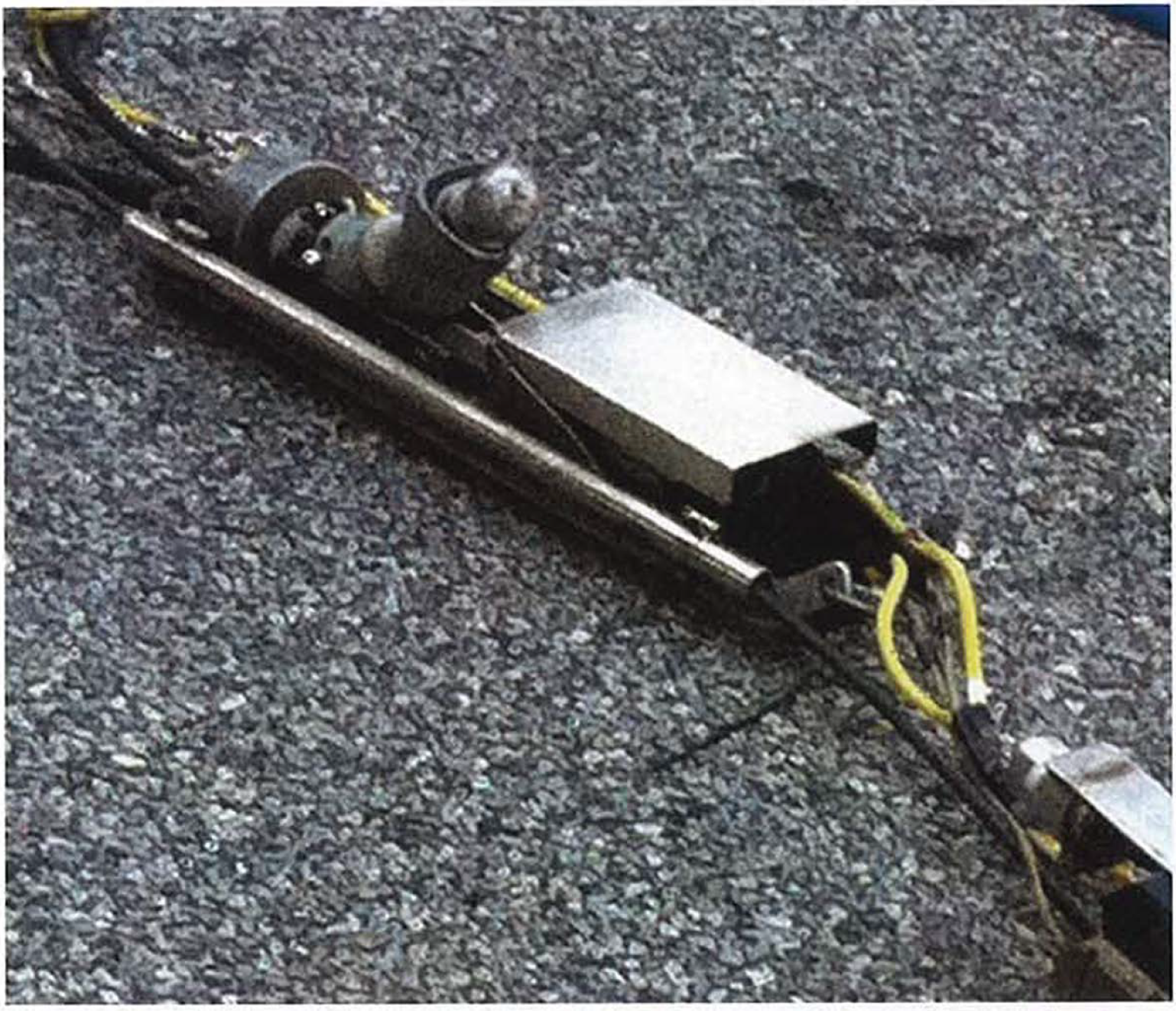

A device, which is commonly referred to as a lateral cleaning launcher is positioned in the mainline sewer using a CCTV camera. This launcher contains a rotation motor that allows the positioning of a sewer cleaning hose and nozzle at the entrance of the sewer lateral.

The sealing of lateral connections with d1emical grout is a proven technique to permanently eliminate infiltration from a collection system. It is a widely used method and one that many communities incorporate within their pipe lining projects to maximize their sewer rehabilitation dollars. Studies have shown that grout sealing lateral connections after sewer lining can provide up to an additional 20 percent reduction in infiltration.

As with any trenchless technology, the lateral connection must be clean enough to allow a lateral packer to seal the mainline on either side of the tap, and within the lateral itself, in order to achieve an effective, long-term seal. The development and advancements of equipment specifically designed for cleaning laterals from the mainline sewer has greatly increased the number of lateral connections that can be successfully grout sealed. The net result of more lateral connections being grout sealed on a rehab project is greater infiltration reduction.

In the past, if roots or light mineral deposits were encountered in the lateral connection, the lateral was either "skipped" or expensive and time-consuming measures were executed to clean the lateral sewer from a cleanout inside the home. Today, a crew can execute lateral clea1ling by using their existing mainline cctv equipment in conjunction with a jet truck (or combination machine).

The process is rather simple. A device, which is commonly referred to as a lateral cleaning launcher (see photo), is positioned in the mainline sewer using a cctv camera. This launcher contains a rotation motor that allows the positioning of a sewer cleaning hose and nozzle at the entrance of the sewer lateral. In most instances, a small diameter hose (1/2 in.) is used for this operation, as most laterals are only 4 to 6 in. in diameter. Once pressurized, the hose/nozzle launches into the lateral much like that of a jet truck nozzle launching up a mainfu1e sewer.'Ihe efficiency of this procedure can be greatly improved through the use of higher pressures (greater than 3,000 psi) or rotating nozzles.

Roots and light mineral deposits are easily removed with this technique, however, not all laterals need to be cleaned prior to connection grout sealing. The lateral does not need to be spotless - it just needs to be sufficiently clean to allow proper positioning and seating of the lateral connection packer. lt should be noted that the lateral cleaning procedure is different than mainline sewer cleaning and should be clearly identified in the project specifications. Simply including lateral cleaning in the mainline cleaning and televising section of the project specifications will likely result in a dispute or extra work order request by the contractor. Thus, the specifying engineer should consider adding a pay item for "lateral cleaning from the mainline sewer" when specifying lateral connection sealing with chemical grout. By providing such item, the owner gets the benefits of an increase in the number of connections sealed while only paying for the lateral cleaning when it is required.

This procedure is also used when preparing a lateral for lining. In some instances, the use of this procedure can preclude the need to install an outside cleanout.

The Infiltration Control Grouting Association (ICGA) recently prepared a Standard Specification for Sealing Pipe Joints, Laterals and Lateral Connections, incorporating this procedure and identifying the proper pay items for lateral connection grout sealing project. This standard specifications is available for free and can be downloaded at www.sewergrouting.com.

This article was written by NASSCO's Lateral Committee.

For more information call 1-800-246-5988 or email info@logiball.com

Follow us on LinkedIn

Follow us on LinkedIn Follow us on YouTube

Follow us on YouTube